Trusted company that deals in quality-made products

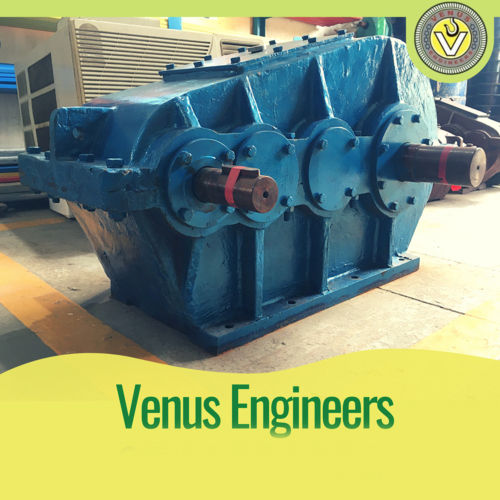

Standard Helical Gearbox

20000.00 - 100000.00 INR/Unit

Product Details:

- Gear Type Helical

- Material Cast Iron / Alloy Steel

- Processing Type Precision Machined

- Gear Tooth Profile Helical

- Gearing Arrangement Parallel

- Direction Bi-Directional

- Output Torque Up to 3500 Nm

- Click to view more

X

Standard Helical Gearbox Price And Quantity

- 1 Unit

- 20000.00 - 100000.00 INR/Unit

- Natural / Fan Cooled

- 1.5

- Up to 20:1

- Oil Splash / Forced Lubrication

- Low

- IP55 / IP65

- Sturdy Ribbed Design

- Foot / Flange Mounted

- Conveyors, Mixers, Crushers, Material Handling Equipment

Standard Helical Gearbox Product Specifications

- Up to 150 kW

- Up to 96%

- Cast Iron / Alloy Steel

- Parallel

- 415V AC

- Helical

- Up to 1800 RPM

- Up to 350 RPM

- Helical

- Up to 3500 Nm

- Precision Machined

- Bi-Directional

- Natural / Fan Cooled

- 1.5

- Up to 20:1

- Oil Splash / Forced Lubrication

- Low

- IP55 / IP65

- Sturdy Ribbed Design

- Foot / Flange Mounted

- Conveyors, Mixers, Crushers, Material Handling Equipment

Standard Helical Gearbox Trade Information

- 20 Unit Per Year

- Week

- All India

Product Description

We have marked a distinct position in this field by providing excellent grade Standard Helical Gearbox. The offered gearbox is manufactured using quality assured components by a troop of adroit professionals with the aid of contemporary techniques. This is widely used in chemical, cement, transportation and textile industries. In addition, our valued clients can easily purchase this productat industry leading prices.

Standard Helical Gearbox Features:

- Optimum performance

- Long lasting nature

- Higher strength

- Flawless finish

Versatile Mounting and Strong Construction

Choose between foot or flange mounting options to fit various installation needs. The housing is constructed from durable cast iron or alloy steel with a ribbed design, ensuring superior mechanical strength and optimal cooling. This makes the gearbox reliable in harsh industrial environments where longevity and dependability are paramount.

Efficient Lubrication and Cooling Methods

Helical gearboxes feature oil splash or forced lubrication systems to maintain smooth operation and reduce wear. They also offer natural or fan-based cooling, allowing them to perform efficiently in high-load or continuous operation scenarios. These features contribute significantly to extending service life and minimizing maintenance requirements.

Precision Performance and Application Flexibility

With a precision-machined helical gear tooth profile and a parallel gearing arrangement, these gearboxes offer bi-directional operation and impressive output torque up to 3500 Nm. Typical applications include conveyors, crushers, mixers, and a range of material handling equipment across various industries including manufacturing and export sectors.

FAQs of Standard Helical Gearbox:

Q: How is the Standard Helical Gearbox typically installed?

A: Depending on the application, this gearbox can be mounted using either the foot or flange method. The choice allows for flexible integration into existing machinery, making it suitable for a wide range of industrial installations.Q: What lubrication and cooling options are available for this gearbox?

A: The gearbox provides oil splash and forced lubrication options to ensure optimal gear performance and longevity. For cooling, users can select between natural convection or a fan-cooled system based on operational load and ambient temperature.Q: When should I consider using a helical gearbox with a reduction ratio up to 20:1?

A: A reduction ratio up to 20:1 is ideal when significant torque multiplication and controlled output speed are required, as in heavy-duty conveyor systems, mixing equipment, or crushers handling variable loads.Q: Where are these gearboxes most commonly used?

A: They are primarily installed in industrial applications such as conveyors, material handling systems, mixers, and crushersespecially where high reliability, low noise, and robust construction are needed.Q: What is the process for selecting the right gearbox for my needs?

A: Selection depends on required output torque, input/output speeds, application type, mounting preference, and environmental factors. Consulting with a distributor or supplier ensures the model matches your specific operational requirements.Q: How does the ribbed housing design benefit the gearbox?

A: The sturdy ribbed housing not only enhances mechanical strength but also improves thermal dissipation, which reduces the risk of overheating during prolonged or intense operation, contributing to overall gearbox longevity.Q: What are the primary benefits of using a precision machined helical gearbox?

A: Precision machining ensures high efficiency (up to 96%), low noise operation, and smooth bi-directional performance, making these gearboxes an excellent choice for industrial environments requiring consistent and reliable power transmission.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email