Trusted company that deals in quality-made products

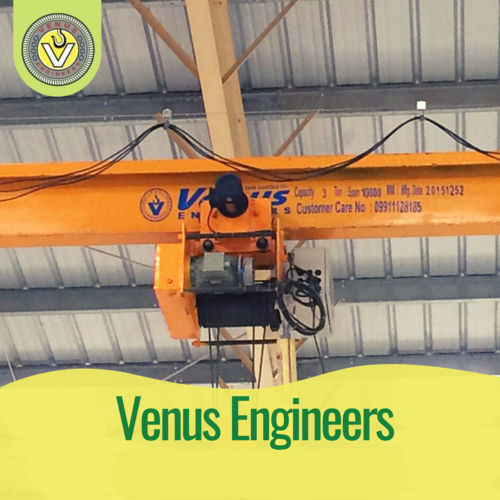

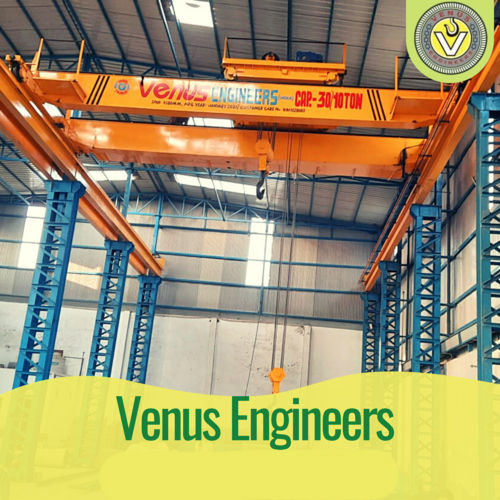

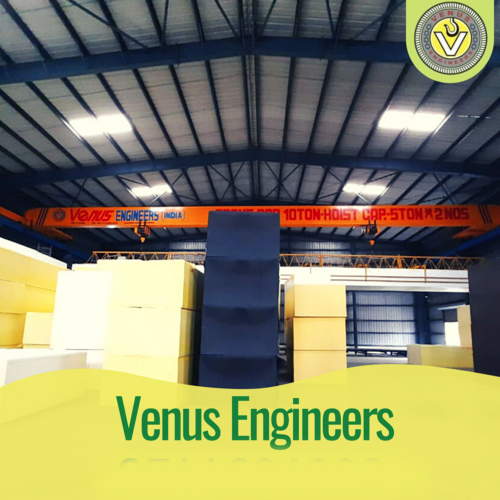

Overhead Travelling Cranes

400000.00 - 1200000.00 INR/Unit

Product Details:

- Loading Capacity Up to 25 Ton (customizable as required)

- Feature Robust construction, precise load movement, and long service life

- Crane Total Weight As per model (varies with configuration)

- Type Overhead Travelling Crane

- Condition New

- Girder Single or Double Girder options available

- Max. Lifting Load 25 Ton

- Click to view more

X

Overhead Travelling Cranes Price And Quantity

- 400000.00 - 1200000.00 INR/Unit

- 1 Unit

- Wire rope hoist or chain hoist

- Rigid box type construction, precision engineered wheels

- A3~A7 (ISO/FEM Standards)

- Anti-rust primer & finishing paint

- Low, <75 dB

- On-site installation and commissioning available

- Factory, Warehouse, Workshop, Heavy Engineering

- -20°C to +40°C

- Pendant control / Remote control / Cabin control

- High quality steel

- Low Maintenance, Easy Serviceability

- Span, Lifting Height, Control System, Hoist Type

- Motor driven with reduction gearbox

Overhead Travelling Cranes Product Specifications

- As per model (varies with configuration)

- 500015000 W depending on size

- 25 Ton

- Single or Double Girder options available

- Travel speed up to 20 m/min

- Robust construction, precise load movement, and long service life

- 380V / 415V, 3 Phase, 50/60 Hz

- Electric

- Up to 25 Ton (customizable as required)

- Up to 20 meters

- Overhead Travelling Crane

- Limit switch, overload protection, emergency stop

- New

- Depend on capacity (approx. 5-15 kW)

- Up to 30 meters or customized

- Wire rope hoist or chain hoist

- Rigid box type construction, precision engineered wheels

- A3~A7 (ISO/FEM Standards)

- Anti-rust primer & finishing paint

- Low, <75 dB

- On-site installation and commissioning available

- Factory, Warehouse, Workshop, Heavy Engineering

- -20°C to +40°C

- Pendant control / Remote control / Cabin control

- High quality steel

- Low Maintenance, Easy Serviceability

- Span, Lifting Height, Control System, Hoist Type

- Motor driven with reduction gearbox

Overhead Travelling Cranes Trade Information

- 12 Unit Per Year

- 5 Week

Product Description

These are Overhead Travelling Cranes are popular in the market for their optimum quality and excellent workability. Our offered machines are widely used for handling raw materials. These are acknowledged for their high speed performance, simple operations and heavy load bearing capability. In addition to this, the said Overhead Travelling Cranes are robust in construction and ensure seamless finishing. These are found in construction industries and other sectors for lifting and transporting heavy objects from one place to another in hassle free manner. Furthermore, the said machines are undergone heat treatment for acquiring robustness and corrosion resistance.Features:

- These are known for their trouble free functioning

- Our machines are easy to operate and ensure optimum service

- Due to simple features the process becomes convenient & smooth

- Consume less energy and require low maintenance

Product details

|

Surface Treatment |

Color Coated |

|

Load Capacity |

30-40 ton |

|

Max Height |

60-80 Feet |

|

Power Source |

Electric |

|

Hoist Travelling Speed |

0-5 m/min |

|

Span |

1 - 30 m |

Versatile Applications and Strong Construction

Designed for use in factories, warehouses, workshops, and heavy engineering sites, these overhead travelling cranes are fabricated from premium steel and feature robust construction. The cranes cater to demanding industrial needs, ensuring durability even in harsh conditions. Rigid box-type end carriages and precision-engineered wheels further enhance stability and load handling during demanding operations.

Customizable Load Handling and Controls

Adapt your crane to your sites layout with customizable span, lifting height (up to 20 meters), and control methods including pendant, wireless remote, or cabin controls. The option of wire rope or chain hoists and easy configurability of hoisting and control systems guarantee precise load movement and increased productivity for a wide range of material handling requirements.

Quiet, Efficient, and Safe Operations

Engineered to operate at low noise levels (below 75 dB), these cranes minimize workplace disruptions. Integrated safety systems such as overload protection, limit switches, and emergency stop ensure reliable and safe operations. Anti-rust primer and finishing paint safeguard the cranes for long-term service, and the cranes are designed for low maintenance with easy serviceability.

FAQs of Overhead Travelling Cranes:

Q: How is the Overhead Travelling Crane installed and commissioned on-site?

A: Professional on-site installation and commissioning are provided by our expert team. The process includes setting up the crane structure, assembling the end carriages, installing the hoisting mechanism, configuring the control system, and thoroughly testing all functions to ensure safety and reliable operation before handover.Q: What customization options are available for these cranes?

A: You can customize the cranes span (up to 30 meters), lifting height (up to 20 meters), hoist type (wire rope or chain), control method (pendant, remote, or cabin), and several other specifications to suit your facilitys requirements. Loading capacity is also adjustable up to 25 tons depending on your application.Q: When should I use a single girder versus a double girder overhead crane?

A: Single girder cranes are ideal for lighter loads and shorter spans, offering cost-effectiveness. Double girder cranes are preferable for heavier loads, longer spans, or greater lifting heights, as they provide enhanced strength, stability, and hook height.Q: Where can these cranes be used effectively?

A: These overhead travelling cranes are optimal for factories, warehouses, general workshops, and heavy engineering facilities requiring reliable, robust material handling equipment. Their versatility suits both new installations and upgrades in industrial settings.Q: What maintenance procedures are required and how easy are they to service?

A: These cranes are engineered for low maintenance, featuring easily accessible components for inspection and servicing. Routine checks for lubrication, tightness, and proper functioning of safety features are recommended. Spare parts and service support are readily available to ensure minimal downtime.Q: How do the safety systems enhance crane operation?

A: Advanced safety mechanismssuch as overload protection, limit switches, and emergency stopactively prevent accidents, safeguard operators, and protect goods. These systems comply with ISO/FEM standards, ensuring industry-leading safety for continuous operation.Q: What are the benefits of using a motor-driven crane with a reduction gearbox?

A: Motor-driven operation with a reduction gearbox allows for smooth, precise travel and heavy load handling with minimal effort. This setup optimizes energy use, enhances precision in load placement, and contributes to the equipments long service life.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email