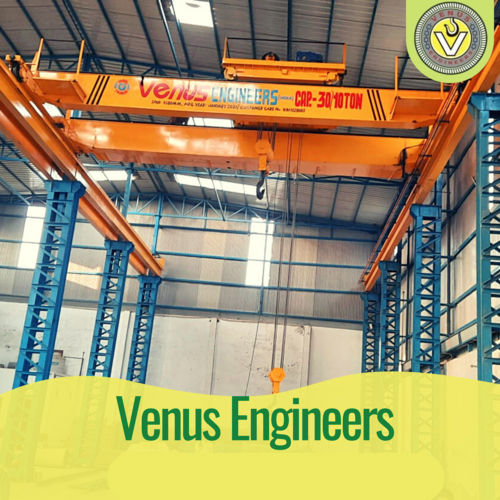

Heavy Duty EOT Cranes

Product Details:

- Traveling Speed 20-40 m/min

- Brake Electro Hydraulic Thruster Brake

- Electric Hoist Included

- Application Industrial, Construction, Warehouse, Manufacturing

- Emergency Stop Yes

- Gearbox Heavy Duty Helical Type

- Color Yellow/Customized

- Click to view more

Heavy Duty EOT Cranes Price And Quantity

- 1 Unit

- 500000 INR/Unit

- High-grade Steel

- Heavy Duty (IS:807 & IS:3177 standards)

- Open Winch Type

- PLC Based Panel with Overload Protection

- Included for Hoisting & Travel

- Double Girder EOT Crane

- Standard Industrial Environment

- Customized as per Requirement

- IS, FEM, DIN, ISO

- IP54/55

- Anti-corrosive Epoxy Coating

- Minimum hook approach for maximum coverage

- -20°C to +55°C

- Class F

Heavy Duty EOT Cranes Product Specifications

- Up to 100 Ton

- 20-40 m/min

- Up to 30 m

- As per specification

- Wire Rope Hoist/Double Girder Trolley

- 3 Phase AC

- Electro Hydraulic Thruster Brake

- 380-440V

- Included

- Yes

- Industrial, Construction, Warehouse, Manufacturing

- Up to 100 Ton

- 5-20 m/min

- Heavy Duty Helical Type

- New

- Yellow/Customized

- 18 m

- Cabin, Pendant or Remote Control

- High-grade Steel

- Heavy Duty (IS:807 & IS:3177 standards)

- Open Winch Type

- PLC Based Panel with Overload Protection

- Included for Hoisting & Travel

- Double Girder EOT Crane

- Standard Industrial Environment

- Customized as per Requirement

- IS, FEM, DIN, ISO

- IP54/55

- Anti-corrosive Epoxy Coating

- Minimum hook approach for maximum coverage

- -20°C to +55°C

- Class F

Heavy Duty EOT Cranes Trade Information

- 20 Unit Per Year

- 100 Week

- All India

Product Description

Offered Heavy Duty EOT Crane can bear 5 ton to 10 ton load. Its travelling speed in every minute is 0.5 m and it can cover 10 m to 20 m distance at a stretch. Made of mild steel, this electricity driven crane has double girder type design. Application of this Heavy Duty EOT Crane can be noticed in large construction projects. Offered material handling equipment has F class insulation and IP54 protection rating. It comprises of standard components like buffer motor drive, lubrication unit and roller bearings. As part of its safety features, this crane is protected against low voltage condition, weight overload and power overload functions.

Heavy Duty Electric Overhead Travel Crane Details:

|

Max Load Capacity |

5-10 ton |

|

Travel Speed |

0-5 m/min |

|

Girder Type |

Double |

|

Span |

10-20 m |

|

Power Source |

Electric |

|

Material |

Mild Steel |

Superior Structural Integrity

Fabricated from high-grade steel and finished with anti-corrosive epoxy coating, the double girder EOT crane is built to withstand heavy-duty industrial usage. Its robust construction ensures durability, longevity, and secure operation even in challenging climates. Designed for compliance with IS:807 & IS:3177 standards, the crane provides enhanced resistance against wear and corrosion.

Advanced Control and Safety

Equipped with a PLC-based panel incorporating overload protection, emergency stop, and limit switches for hoisting and travel, this crane ensures optimum safety during operations. The inclusion of electro hydraulic thruster brakes and heavy-duty helical gearboxes adds reliability, while the insulation Class F and IP54/55 motor protection safeguard against electrical hazards.

Flexible and Efficient Operation

The crane offers multiple operating modes, including cabin, pendant, or remote control, and is designed for minimal hook approach, maximizing the area covered. Its lifting mechanism uses a wire rope hoist/double girder trolley with speeds between 5 to 20 m/min. The open winch type trolley and customizable configurations cater to various industrial needs, making it an ideal choice for bulk material handling.

FAQs of Heavy Duty EOT Cranes:

Q: How does the Heavy Duty Double Girder EOT Crane ensure operational safety?

A: Operational safety is prioritized through features like PLC-based overload protection, emergency stop, electro hydraulic thruster brakes, and limit switches for both hoisting and travel. Class F insulation and IP54/55 motor protection further minimize risks during lifting operations.Q: What industrial sectors can benefit from installing this EOT crane?

A: Industries such as manufacturing, construction, warehousing, and heavy engineering find the crane especially useful, given its robust design, high load capacity (up to 100 tons), and reliable performance in demanding environments.Q: When is this crane ideal for use in an industrial setting?

A: The crane is suitable for environments requiring frequent heavy lifting, such as production lines, steel plants, assembly halls, and storage facilities where maximum coverage and continuous operation are essential.Q: Where can the Heavy Duty EOT Crane be customized or installed?

A: As a distributor, exporter, manufacturer, and supplier in India, customization is offered to suit specific requirements, including tailored span, lifting height, operating modes, and control systems. Installation services are available across industrial, construction, and warehousing sites.Q: What process is involved in operating and controlling the crane?

A: Operators can choose from cabin, pendant, or wireless remote control modes. The PLC-based panel simplifies management with automated overload protection, allowing precise control of lifting, traveling, and stopping actions for efficient, organized workflow.Q: What are the usage benefits of the open winch trolley and double girder configuration?

A: The open winch trolley provides maintenance ease and robust performance in high-capacity handling. The double girder configuration ensures a larger hook approach and coverage area, accommodating bigger, heavier loads efficiently.Q: How does the anti-corrosive epoxy coating extend the cranes working life?

A: The anti-corrosive epoxy coating protects structural elements from moisture, chemicals, and harsh temperatures, reducing rust and deterioration, thereby maximizing operational longevity and reducing maintenance needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+