Variable Speed Gear Motor

Product Details:

- Voltage 220 V

- Sealed Type Sealed

- Starting Type Direct On Line (DOL)

- Rated Frequency 50 Hz

- Rated Voltage 220 V

- Torque 2.5 Nm

- Bearing Type Ball Bearing

- Click to view more

Variable Speed Gear Motor Price And Quantity

- 1 Piece

- 40000.00 INR/Unit

- 30000.00 - 50000.00 INR/Unit

Variable Speed Gear Motor Product Specifications

- 4

- AC Induction

- Normal Atmospheric

- 370 Watts

- 50 Hz

- <65 dB

- IP54

- 8 kg

- Variable speed control, Compact design, Low maintenance

- Variable, up to 1440 RPM

- Grey

- Air Cooled

- 0.5 HP

- 370 W

- Flange / Foot Mounted

- 0.5 HP

- Totally Enclosed

- 18 mm

- AC

- Ball Bearing

- Standard Efficiency

- -10C to 50C

- Sealed

- 250 x 140 x 130 mm

- 220 V

- Variable Speed Gear Motor

- Single Phase

- 50 Hz

- 2.5 Nm

- 220 V

- Direct On Line (DOL)

Variable Speed Gear Motor Trade Information

- 20 Piece Per Year

- Week

Product Description

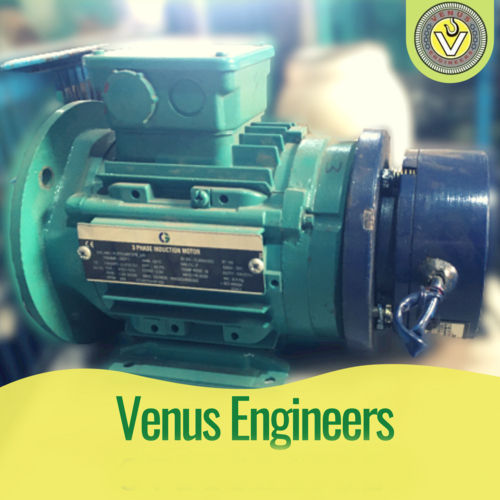

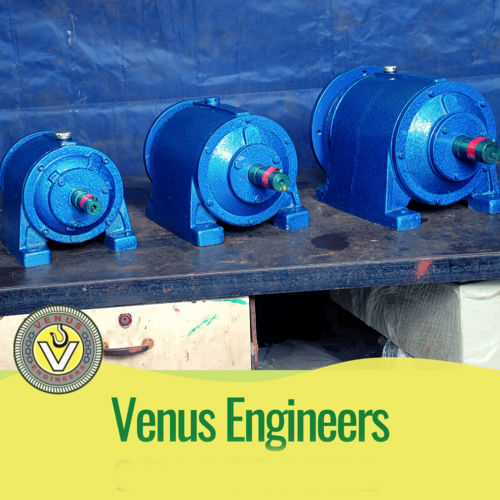

We are a well-known enterprise in this field, engrossed in providing pristine grade Variable Speed Gear Motor. The offered motor is manufactured under the strict supervision of diligent professionals using quality checked components with the implication of progressive techniques. This is widely used in printing, plastic extrusion and other similar machines due to its step-less variation of speed. In addition to this, the provided Variable Speed Gear Motor is available ac competitive prices for our valued patrons.

Features:

- Require less maintenance

- Consume less power

- Easily operated

- Can bear heavy loads

Product Details:

|

Surface Finish |

Paint Coated |

|

Phase |

Three Phase |

|

Packaging Type |

Box |

|

Usage |

Agitation |

|

Power Source |

Electric |

|

Input Power |

0.25 HP to 20 HP |

Versatile Industrial Applications

Designed for horizontal installation, this variable speed gear motor fits a range of scenarios, from conveyors in material handling to lift systems and industrial mixers. Its robust cast iron construction and alloy steel helical gears provide dependable performance, even in continuous operational environments involving machine tools and automated systems.

Rugged Construction and Efficient Cooling

With its cast iron body, the motor is both durable and resilient. The TEFC (Totally Enclosed Fan Cooled) design offers excellent protection against dust and moisture (IP54 rating), while air cooling ensures reliable temperature management during nonstop operation, making it suitable for demanding industrial settings.

Precision Control and Quiet Operation

Variable speed capabilities and a 1:20 reduction ratio allow precise adjustment of output to match specific requirements. The motor operates smoothly and quietly, generating less than 65 dB of noise, which supports productive and comfortable work environments. Ball bearing support and grease lubrication contribute to low maintenance needs.

FAQs of Variable Speed Gear Motor:

Q: How does the variable speed control function benefit industrial applications?

A: The variable speed control enables operators to precisely adjust the output RPM to match the specific process demands in conveyors, mixers, or lift systems, enhancing efficiency, reducing energy consumption, and improving product handling and process consistency.Q: What steps are involved in installing this gear motor?

A: To install the motor, ensure horizontal alignment and secure it using the provided flange or foot mounting options. Connect the wiring to the single-phase 220V AC supply and use Direct On Line (DOL) starting. Double-check that the enclosure is properly sealed for IP54 protection before operation.Q: Where can this gear motor be utilized effectively?

A: The gear motor is ideal for use in various settings such as conveyor systems, machine tools, elevator mechanisms, and industrial mixers, particularly where variable speeds and reliable, continuous performance are required.Q: When is maintenance required, and what does it involve?

A: Scheduled maintenance is minimal due to the grease-lubricated gears and sealed design. Regular checks should include verifying lubrication, inspecting seals, and ensuring unobstructed air cooling. No frequent intervention is typically necessary.Q: What are the main benefits of using a helical gear system in this motor?

A: Helical gears ensure smoother and quieter transmission with higher load capacity compared to spur gears, minimizing vibration and wear. This results in efficient operation and longer service life in demanding environments.Q: How does the totally enclosed fan cooled (TEFC) enclosure enhance motor reliability?

A: The TEFC enclosure protects internal components from dust, dirt, and moisture, contributing to a long operational lifespan. It uses an external fan to maintain optimal cooling during continuous service, even in harsh industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+