Single Girder I-Beam Crane

Product Details:

- Feature Robust structure, easy installation, precise control, high efficiency

- Power Source Electric

- Condition New

- Crane Total Weight Approx. 2 10 Tons (Varies by model and configuration)

- Application Industrial material handling, warehouses, workshops, factories

- Span Length 5 30 meters (customizable)

- Loading Capacity 500 kg to 20 tons (depending on design)

- Click to view more

Single Girder I-Beam Crane Price And Quantity

- 220000.00 - 720000.00 INR/Unit

- 1 Unit

Single Girder I-Beam Crane Product Specifications

- Yes, installed for safety

- Up to 18 meters (customized)

- 1 to 20 tons

- New

- Electric

- Robust structure, easy installation, precise control, high efficiency

- 500 kg to 20 tons (depending on design)

- Industrial Yellow/Customizable

- Industrial material handling, warehouses, workshops, factories

- Approx. 2 10 Tons (Varies by model and configuration)

- Yes, equipped

- Varies by capacity, typically 812 m/min lift speed

- 5 30 meters (customizable)

Single Girder I-Beam Crane Trade Information

- 20 Unit Per Year

- Week

- Wooden packing

- All India

- ISO 9001:2018

Product Description

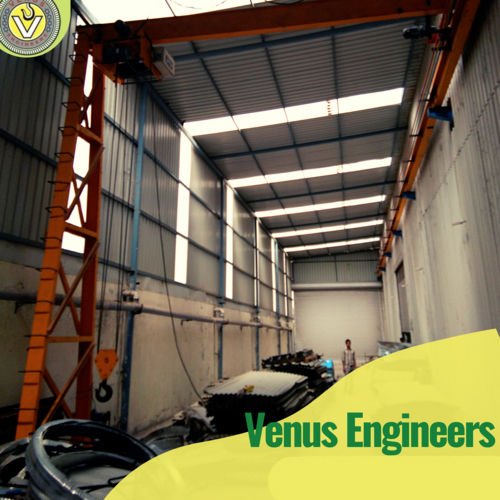

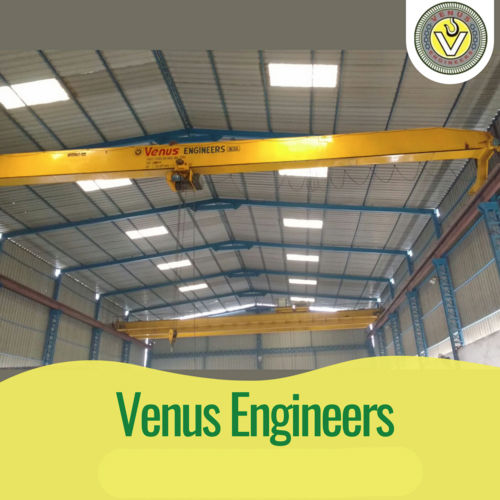

Our well-equipped infrastructure facility has enabled us to provide Single Girder I Beam Crane. These cranes are widely demanded in factories, foundry and workshops due to their high performance and durability. Premium grade components and materials like mild steel sheets, mild steel angles, I beam, motors and brakes are used in these machines. Our clients can avail the I Beam Single Girder Crane in many specifications at market leading prices. Furthermore, these cranes are quality tested before delivery to ensure efficiency and the satisfaction of our clients.

Some of the unique features of Single Girder I-Beam Crane:

1) High performance

2) Durable

3) Sturdy

4) Easy maintenance

5) Corrosion resistance

Specifications:

1) Design : Compact dimensions, low weight, easy to operate and easy to maintain.

2) Motors : Motors will be Crane duty motors, squirral cage induction motors for hoists and cranes also slipering induction motors will be provided for heavy duty cranes as per the applications.

3) Gear Boxes : Precision flat helical / spur gear units in light alloy housings with case-hardened gears, high-grade surface treatment and permanent oil /grease lubrication.

4) Brakes : Single / Dual-disc Electro Magnetic DC Brakes featuring automatic braking on power failure.

Product details

|

Girder Type |

Single |

|

Span |

1-10 m |

|

Capacity |

5-10 ton |

|

Power Source |

Hydraulic |

|

Hoist Travelling Speed |

0-5 m/min |

|

Max Height |

20-40 feet |

Versatile Application & Durable Construction

Designed for a range of industrial environments, this single girder I-beam crane excels in warehouses, factories, and workshops. Its robust structural components and weather protection options enable smooth, safe operation both indoors and outdoors, ensuring long service life under intensive usage.

Enhanced Safety and Precise Operation

Integrated with advanced features like an electromagnetic automatic brake, limit switches, and a reliable emergency stop, this crane prioritizes operator and load safety. Precise control mechanisms allow for accurate material placement, while easy-to-use controls support smooth, efficient operations.

Customizable to Fit Project Requirements

Available with a wide range of span lengths (530 meters), lifting heights (up to 18 meters), and lifting capacities (120 tons), the crane is fully customizable. Clients may specify mounting type, color, hoist type, and power supply configuration, ensuring an optimal fit for any industrial workflow.

FAQs of Single Girder I-Beam Crane:

Q: How is the Single Girder I-Beam Crane typically installed in an industrial facility?

A: The crane features a modular and easy assembly design, allowing for efficient installation as either a floor-mounted or ceiling-suspended unit. Installation is straightforward and can be adapted to suit your facilitys specific spatial and operational requirements.Q: What are the main benefits of using an electric wire rope or chain hoist with this crane?

A: Both electric wire rope and chain hoists deliver high efficiency, robust lifting capabilities, and precise control. The choice between them depends on load requirements and site conditions, ensuring improved safety and productivity for diverse industrial handling applications.Q: When should I consider outdoor weather protection options for this crane?

A: Outdoor installation or environments exposed to the elements necessitate weather protection features to maintain optimal performance and extend equipment lifespan. Weather-resistant versions are available to safeguard against rain, dust, and extreme temperatures.Q: Where can this crane be used within an industry or facility?

A: The crane is ideal for indoor and outdoor applications such as warehouses, manufacturing plants, assembly lines, and maintenance workshops. Its versatility and customizable features adapt to various industrial workflows and handling requirements.Q: What safety features are installed on the crane to protect operators and loads?

A: Key safety features include an electromagnetic automatic brake, limit switches to prevent over-travel, an emergency stop system, and compliance with IS/ISO/CE standards. These mechanisms ensure enhanced operator safety and protect both the crane and handled materials.Q: How does the noise level of the crane impact workplace environments?

A: Operating at noise levels below 75 dB, the crane supports a quieter work environment, reducing noise-related fatigue and improving overall operator comfort and communication in busy industrial settings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+