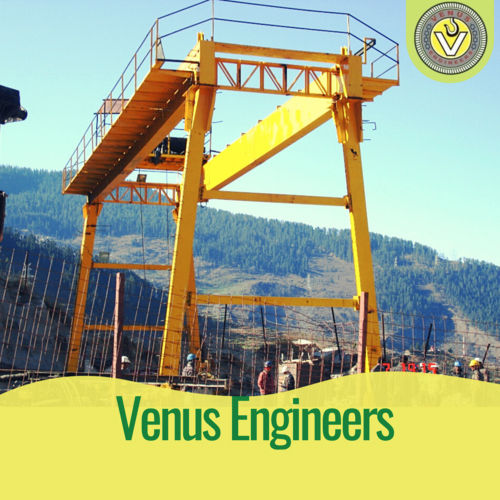

Double Girder Box Type Goliath Cranes

Product Details:

- Working Presssure N/A (not hydraulic)

- Power Supply 3 Phase AC, 380V/415V, 50Hz/60Hz

- Trolley Travel Speed 10-20 m/min (customizable)

- Emergency Stop Provided as standard safety feature

- Crane Total Weight Varies (approx. 20-75 Ton depending on size/capacity)

- Lifting Time As per application requirements

- Feature High Efficiency, Robust Construction, Weather Resistant

- Click to view more

Double Girder Box Type Goliath Cranes Price And Quantity

- 1 Ton

- 500000.00 INR/Metric Ton

- 500000.00 - 980000.00 INR/Metric Ton

Double Girder Box Type Goliath Cranes Product Specifications

- As per design (contact manufacturer)

- Up to 40 meters

- As per application requirements

- Up to 100 Tons (varies based on design)

- 100 Tons

- High Efficiency, Robust Construction, Weather Resistant

- Wire Rope

- Double Girder Box Type Goliath Crane

- Electric Hoist

- N/A (not hydraulic)

- Up to 30 meters

- Provided as standard safety feature

- 10-20 m/min (customizable)

- 3 Phase AC, 380V/415V, 50Hz/60Hz

- 5-15 m/min (adjustable)

- Cabin control, Pendant control, or Radio Remote Control

- Varies (approx. 20-75 Ton depending on size/capacity)

Double Girder Box Type Goliath Cranes Trade Information

- Available

- 2 Ton Per Week

- Week

- Container Packing

- All India

- ISO 9001:2015

Product Description

The Most Portable and Flexible: Gantry Cranes

When it is required to lift a heavy object,Gantry Cranesare employed into use to do the needful. They work by lifting heavy loads with a hoist and can move horizontally over rails that are fitted under beams.

Gantry Cranes are used to lift heavy objects and are frequently used for ship buildings, wherein heavy parts and engines need to be fixed. Developed in modern times, Gantry Cranes are being used on a large scale since their development.

Gantry Cranes move along rails that are fixed on the ground. They are a safer and more efficient option when the use of Overhead cranes is not possible. Both the cranes are handled by one operator, making it less risky for operations.

Gantry/Goliath Cranes: Where they are used?

Gantry Cranes are used in most areas where the heavy lifting of objects is required. A few of them are mentioned below,

- They are used atConstruction siteswhere shifting and moving of building blocks is required.

- Also atharbours,where heavy cargo and boxes need to be moved.

- Gantry cranes are also used forshipbuilding.

- They are used at workplaces where huge bridge cranes cannot be used due to height and weight constraints.

- Gantry cranes are also used atsteel plants, mills,etc

- Places where induction and maintenance of heavy engines and machinery are required.

- Also, other overhead cranes, bridge cranes, etc. cannot be put to use.

Superior Durability and Construction

Manufactured from high-grade mild steel conforming to IS-2062 Gr, these goliath cranes guarantee extended service life even in harsh environments. The robust box-type double girder structure is complemented by a dual-layer paint systemtwo coats of primer and two coats of synthetic enamelproviding exceptional resistance to weather and corrosion.

Efficient and Safe Lifting Operations

Designed for demanding applications, these cranes operate with a working class of M5/M7 as per IS 3177. They feature precise control mechanisms, including electromagnetic or hydraulic brakes and reliable forged steel wheels. Safety is ensured with integrated limit switches and standard emergency stop functions, making them suitable for continuous industrial use.

Versatile Power and Control Options

The Double Girder Box Type Goliath Crane accommodates flexible operational needs with adjustable lifting speeds (515 m/min) and customizable trolley/travel speeds. Operators can choose between cabin, pendant, or radio remote control, optimizing usability for various site requirements. With a 3-phase AC power supply, these cranes seamlessly integrate into modern industrial facilities.

FAQs of Double Girder Box Type Goliath Cranes:

Q: How does the double girder box type design enhance crane performance?

A: The double girder box type structure increases load-bearing capacity and structural stability, enabling the crane to lift up to 100 tons and span up to 40 meters. This design also enhances resistance to torsional stress, making the crane suitable for high-performance industrial operations.Q: What safety features are included with this goliath crane?

A: Safety features include limit switches to prevent over-hoisting and over-lowering, electromagnetic or hydraulic brakes on all movements, an enclosed, dust and weather-proof control panel, and a standard emergency stop function to ensure immediate halting during emergencies.Q: When should this crane be selected over single girder models?

A: Opt for the double girder box type goliath crane when your application demands higher load capacities (up to 100 tons), greater spans (up to 40 meters), or heavier-duty continuous operation, such as in shipyards, heavy manufacturing, or large assembly lines.Q: Where can these cranes be utilized effectively?

A: These cranes are ideally suited for outdoor and large indoor applications, including steel yards, shipyards, construction sites, fabrication shops, and heavy manufacturing units. Their weather resistance and robust construction make them suitable for varied Indian industrial conditions.Q: What is the process for controlling and operating this crane?

A: Operators can choose between cabin, pendant, and radio remote control for flexible operation. The control panel is enclosed and dust/weather-proof, ensuring reliable performance. Operational speeds, including lifting and travel speeds, are adjustable to match specific application needs.Q: What are the primary benefits of using this goliath crane?

A: Key benefits include high efficiency, robust construction, increased safety, weather resistance, and operational versatility. These features translate to reduced downtime, improved productivity, and safe handling of heavy materials in challenging industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Call Me Free

Call Me Free